Designed for quality, reliability and flexibility, the TSCD-II welder is a next-generation, closed-system device that can be used to connect polyvinyl chloride (PVC) tubing in any combination of wet and dry.

The TSCD-II welder may be used across your blood center to connect PVC tubing during tasks, including:

The wafers used by the TSCD-II welder heat up to 300 ̊C, maintaining sterility during cutting and welding without allowing particulates or chemical residue to form in the tubes. The design enables fast, one-handed operation, and durable materials stand up to intensive use.

The TSCD-II welder is available in select markets.

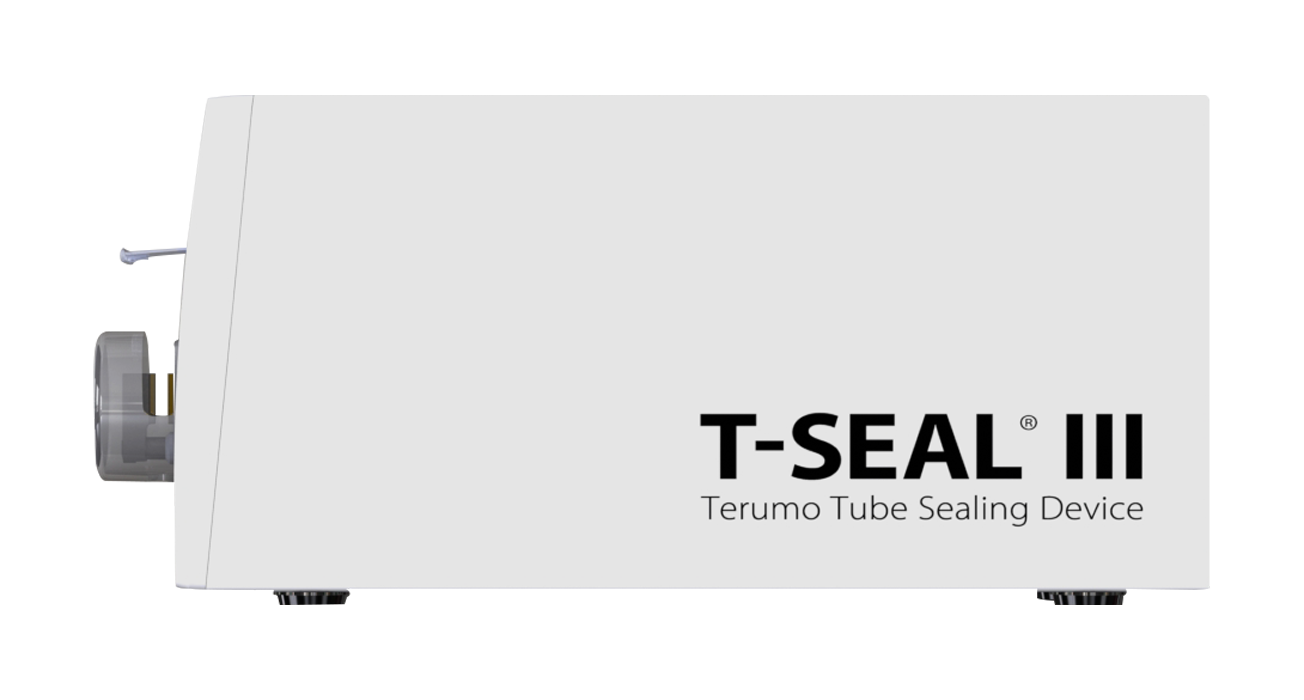

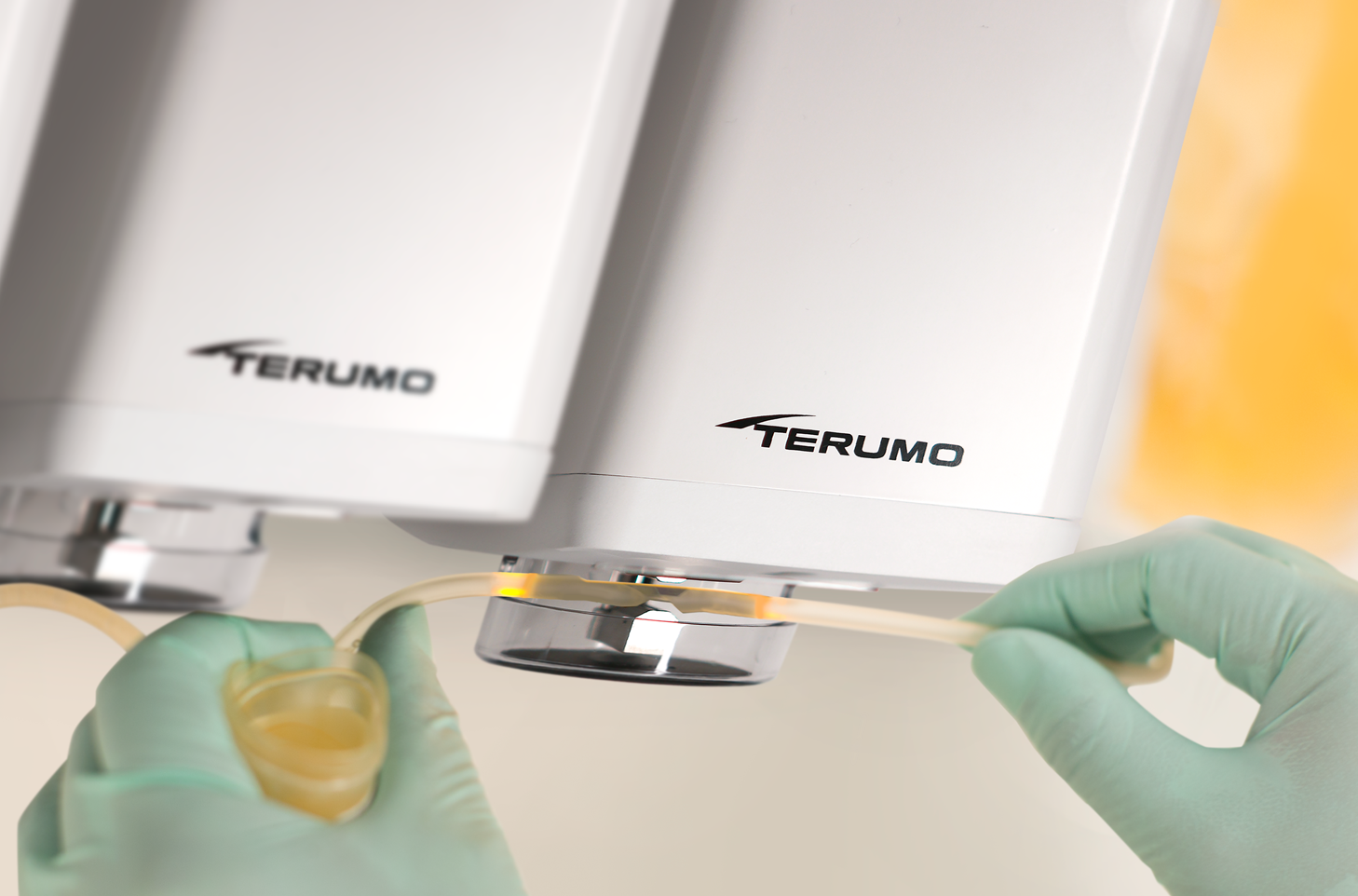

In 3 seconds or less, T-SEAL III creates consistently reliable tubing seals that are easy to separate. Contact your Terumo Blood and Cell Technologies representative today to get started.

PVC: polyvinyl chloride; EVA: ethylene vinyl acetate.

*T-SEAL II is for use with PVC tubing only.

Create dependable tubing seals quickly and easily, wherever you need them, at the donor chair and beyond.

Create dependable tubing seals on the go in just a few steps

T-SEAL Mobile is available in select markets.